FT512 Jumbo Piston Corer

The FT512 Jumbo Piston Corer combines operational safety with survey efficiency. Using proven designs and trusted technologies, the system has the advantage of using both manual and hydrostatic safety release systems.

This Jumbo Piston Corer delivers a longer, and less-disturbed sample than a typical gravity corer, thanks to the piston creating a vacuum, preventing blockages in the sample route.

An extremely flexible piece of equipment, this system is fitted with removable weights which can be configured from 500kg to 4000kg. This means that optimal penetration can always be realised and arranged to match any ground type and your specific survey needs.

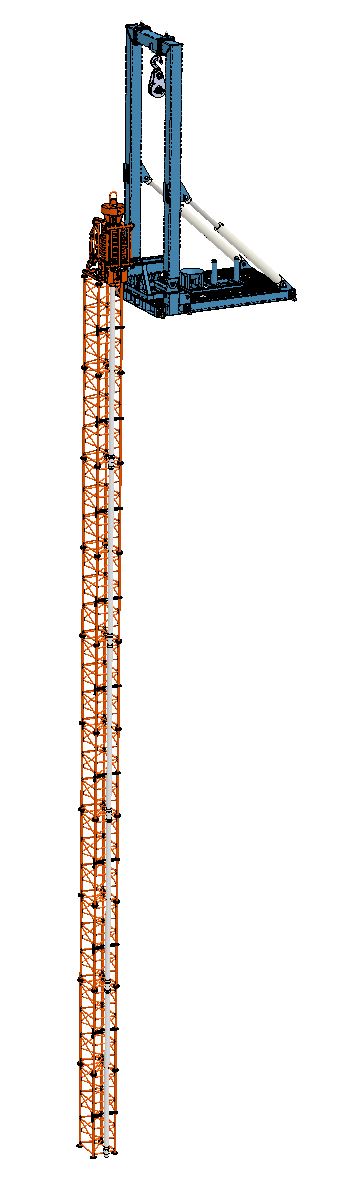

The system can be configured with a barrel length from just 3m to 30m long with easy sample retrieval using quick release connections on the joints. the high weight and short barrels can be used to punch through hard layers within the required sample location.

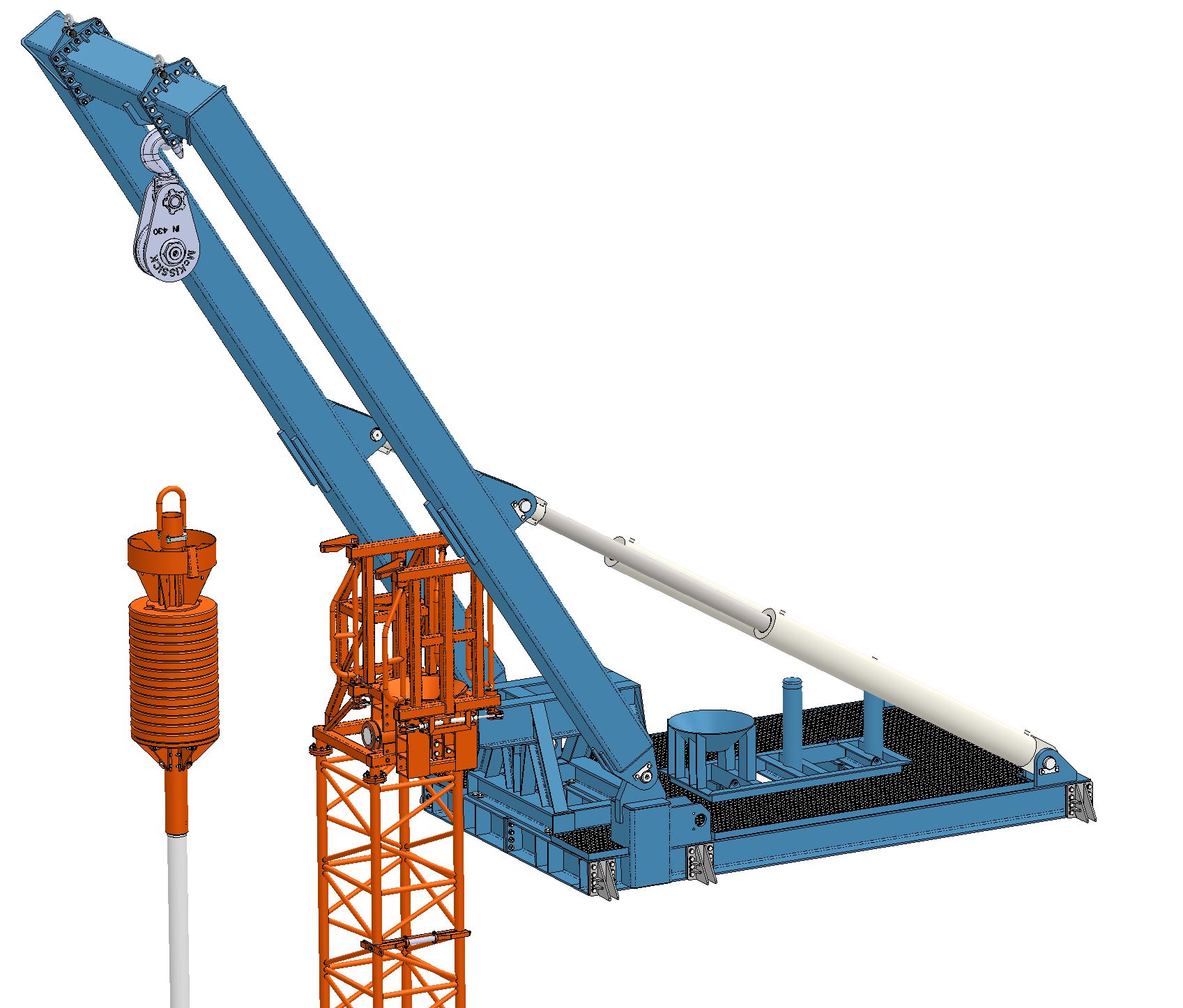

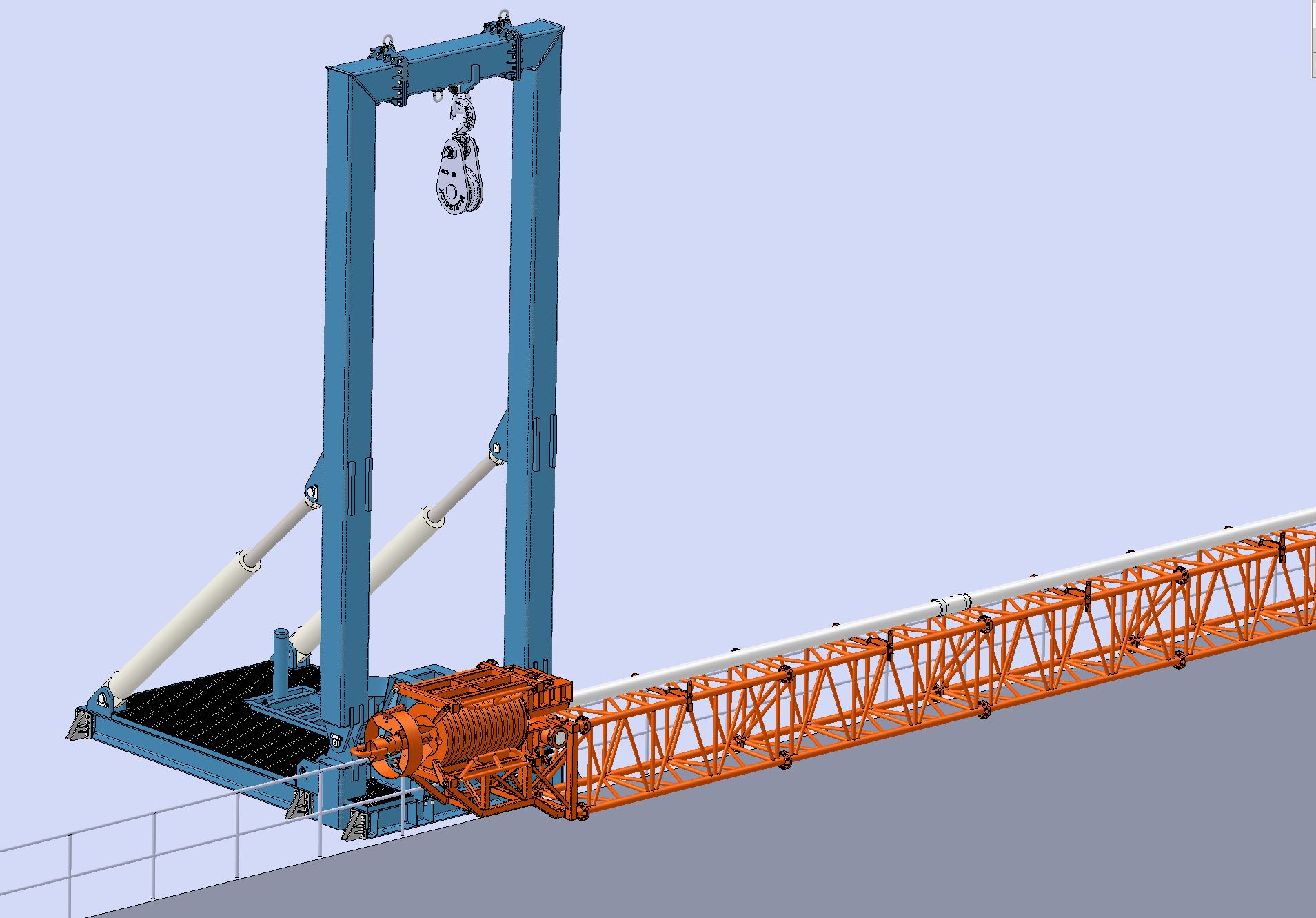

The launch and recovery system (LARS) ensure that this large corer is handled safely and efficiency onboard. Due to the size of the jumbo piston corer, it is not possible to use it without the LARS. we can provide pre-project support to ensure a quick and efficient mobilisation on any suitable vessel of opportunity or a permanent installation on one of your fleet vessels.

please contact us for further information and to discuss you next marine survey project requirements.

Product Highlights

- 3m – 30m long sample (in 3m increments)

- Type C barrel as standard outside diameter 168mm

- Sample size of 120mm

- Other diameter samples available on request

- Hydrostatic safety release system

- Manual or automatic triggers

- Full ocean depth rating

- Configurable weights from 500kg to 4000kg

- Consumables in stock for rapid mobilisation

- Various LARS options available

- Compatible with FT580 Heat Flow System

How does the Jumbo Piston Corer work?

A jumbo piston corer has a wider diameter barrel and can be as much as 30m long whereas a standard piston corer is typically up to 9m long. The trigger mechanism is based around the Kullenberg design and has an acoustic seafloor detection system to aid in triggering at just the right height

On the way down through the water column the Feritech hydrostatic safety release arms at the set depth, this allows the piston corer to release when it reaches the sea floor and increases operational safety

The piston corer is released when our acoustic trigger system detects that it is the correct distance from the sea floor or a weight or small gravity corer on the end of a messenger wire touches the seabed and allows the tripping arm to open.

Once released the main piston corer free falls into the sea floor under its own mass, our system has modular weights and can be set anywhere between 500kg to 4000kg.

As the piston corer penetrates the seafloor, the piston inside stops at the sea floor. As the corer penetrates the action of the piston creates a pressure differential at the top of the sediment column that encourages marine soil to enter the core liner in an undisturbed state.

The Feritech release system using our own trigger grip mechanism ensures a relatively simple recovery.

After a few seconds the coring process is complete, and the system is recovered back on to the vessel using the LARS so that the core can be extracted and processed.